| Feature | Specification |

|---|---|

| Engine | Weichai WP6G140E22, 103 kW (138 HP) |

| Operating Weight | Around 13,500–14,500 kg |

| Transmission | 6 Forward + 3 Reverse speeds |

| Blade Width | 3.7 m (12 ft) |

| Maximum Blade Lift Height | 450 mm |

| Maximum Blade Depth | 610 mm |

| Turning Radius | 5.8 m |

| Fuel Tank Capacity | 250 L |

| Hydraulic Oil Tank Capacity | 120 L |

| Cab | Ergonomic design, air-conditioned, adjustable seat |

| Ground Clearance | 300 mm |

Second-hand GR1803 grader

Fob Price: / Unit

Product Description

TAG:

excavators-used.com

We have a huge collection of used construction machinery including excavators, loaders, bulldozers, cranes, and more. Contact us today!"

When considering a second-hand XCMG GR1803, a thorough inspection of the key components is essential to ensure you're purchasing a reliable machine. Here’s what to focus on:

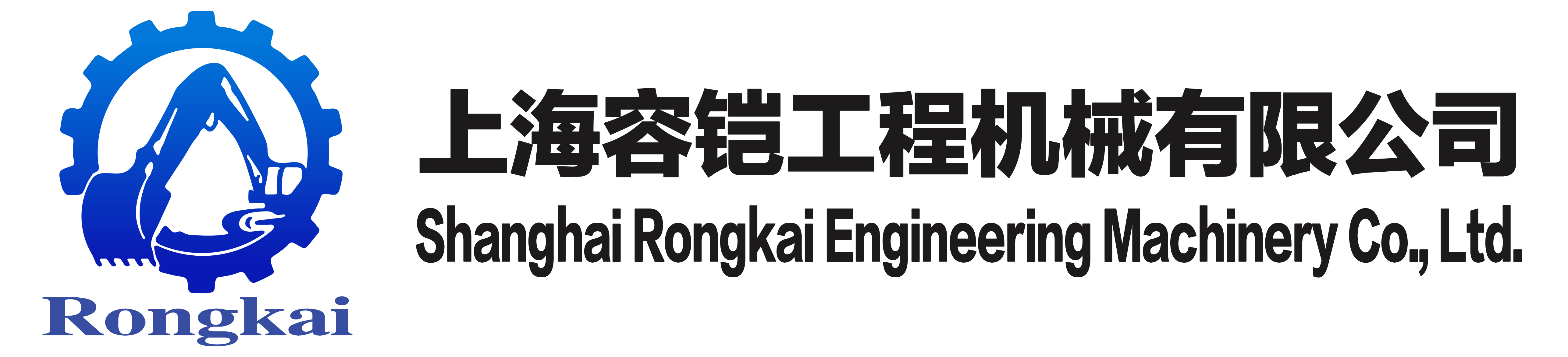

1. Engine and Powertrain

- Engine Condition: The GR1803 typically uses the Weichai WP6G140E22 engine, which provides 103 kW (138 HP). Listen for any unusual sounds during startup and operation, such as knocking or irregular engine noises.

- Oil Leaks: Check the engine and transmission for any oil or coolant leaks. Leaks can indicate potential issues with seals or gaskets that might require repairs.

- Exhaust Smoke: Excessive smoke, especially blue or black smoke, can indicate issues with the engine's combustion process.

- Air Filters and Belts: Inspect the air filters for cleanliness and check the belts for wear and proper tension.

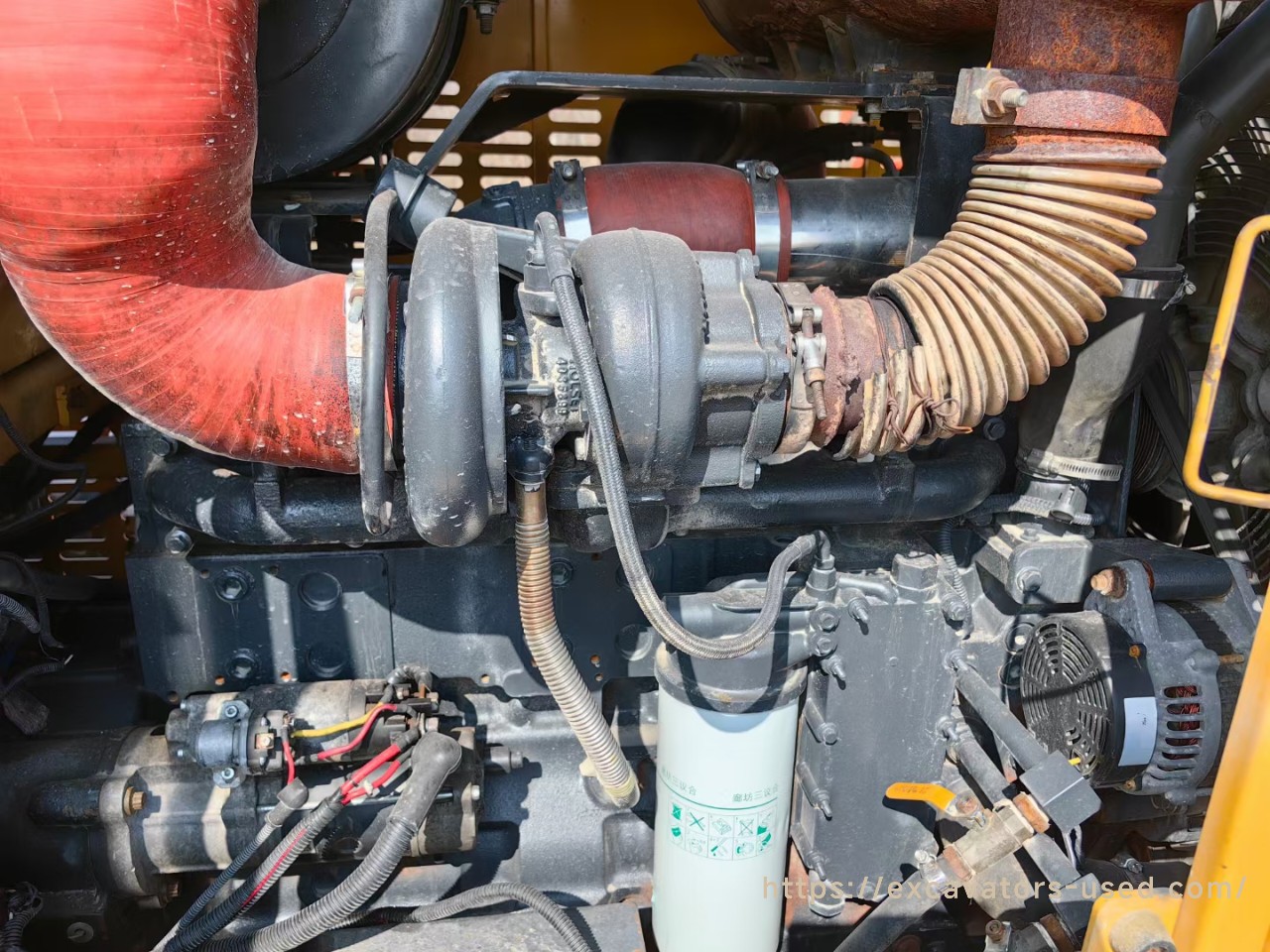

2. Hydraulic System

- The hydraulic system controls key functions like blade lift, tilt, and angle adjustments. Test the operation of these functions to ensure smooth movement without delays or jerks.

- Hydraulic Oil Leaks: Look for leaks around the hydraulic cylinders, valves, and hoses. Leaks can reduce efficiency and indicate the need for component replacement.

- Check the hydraulic oil itself—ensure it’s clean and free from contamination.

3. Transmission and Steering

- The GR1803 grader comes with a 6-speed transmission. Test all gears to ensure they shift smoothly without grinding or hesitation.

- Inspect the steering system for any play or unresponsiveness. Ensure that the machine turns easily and the articulating frame functions without difficulty.

- Check the turning radius to confirm it’s in line with the manufacturer's specifications.

4. Undercarriage and Tires

- Examine the undercarriage for wear and tear. Pay attention to the condition of the frame, axles, and suspension system.

- Tire Condition: Inspect the tires for tread wear, cracks, and any other signs of damage. Tires are a major part of the operating cost, and replacing them can be expensive.

- Ensure that the blade and scarifier are not excessively worn. The blade should have a uniform edge and no cracks.

5. Cab and Operator Controls

- Check the cab for general wear, cleanliness, and damage. Ensure that the seat is comfortable and adjustable, and check the air conditioning system to ensure it works properly.

- Test all controls, including joystick, pedals, and switches, to ensure they operate smoothly without delay.

- The instrument panel should provide accurate readings for fuel, oil pressure, temperature, and other important systems.

6. Electrical System and Lights

- Inspect the wiring for any signs of wear, fraying, or exposure. Damaged wires can lead to electrical issues.

- Test all lights, including headlights, taillights, and indicators, to ensure they are working correctly.

- Check the batteries for corrosion or leakage, and ensure they hold a charge.

7. Service and Maintenance History

- Request the service records for the machine to verify that it has been properly maintained.

- Look for any records of major repairs or replacements, such as engine overhauls, transmission work, or hydraulic component replacement.

- A well-maintained machine is likely to have fewer issues, so a clear service history is crucial.

8. Visual Inspection

- Perform a visual inspection of the entire machine. Look for any cracks, rust, or corrosion on the frame, chassis, or undercarriage.

- Inspect the blade for signs of excessive wear or damage. A worn-out blade can affect the quality of work and may require replacement soon.

- Look at the scarifier (if equipped) for wear, as it’s another key component subject to heavy use.

Related Products