| Feature | Specification |

|---|---|

| Engine | Weichai WP6G180E351, 132 kW (177 HP) |

| Transmission | 6 Forward + 3 Reverse speeds |

| Operating Weight | 17,000 kg |

| Blade Width | 3.7 m (12 ft) |

| Maximum Blade Lift Height | 460 mm |

| Maximum Blade Depth | 460 mm |

| Turning Radius | 6.2 m |

| Fuel Tank Capacity | 280 L |

| Hydraulic Oil Tank Capacity | 150 L |

| Cab | Air-conditioned, ergonomic design |

| Ground Clearance | 375 mm |

Second-hand XCMG GR180 grader

Fob Price: / Unit

Product Description

TAG:

excavators-used.com

We have a huge collection of used construction machinery including excavators, loaders, bulldozers, cranes, and more. Contact us today!"

Tips for Inspecting a Second-hand XCMG GR180 Grader:

-

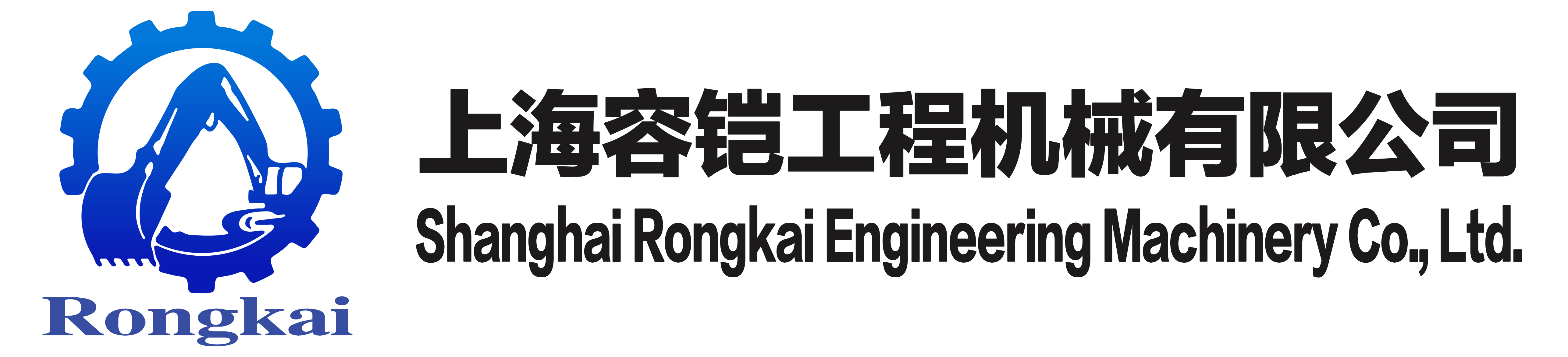

Engine & Powertrain:

- Engine Hours: Check how many hours the engine has been running. A well-maintained second-hand motor grader should have moderate engine hours (e.g., less than 10,000 hours).

- Cold Start Test: Start the engine and listen for any abnormal sounds. It should start smoothly without excessive smoke or noise.

- Performance: Ensure the engine runs smoothly during operation, with consistent power output and no hesitation. A weak engine or inconsistent power can indicate internal issues.

-

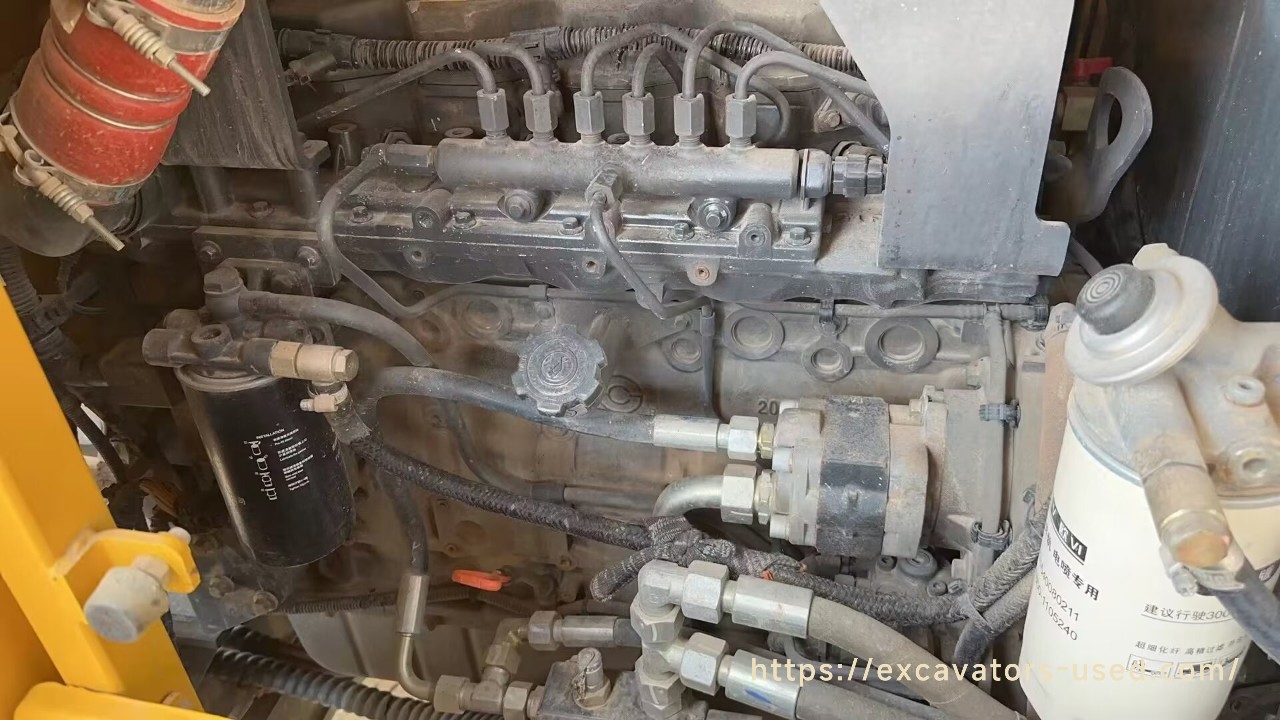

Hydraulic System & Blade Control:

- Hydraulic Leaks: Look for any oil leaks around the hydraulic lines and cylinders. The hydraulic system should be clean and free of leaks to avoid expensive repairs.

- Blade Movement: Test all blade functions (e.g., lifting, tilting, angling, and lowering) to ensure they respond promptly and smoothly. There should be no jerking or sluggishness.

- Hydraulic Fluid Levels: Check the hydraulic fluid levels and the condition of the oil to ensure the system is well-maintained.

-

Transmission & Steering:

- Transmission: Test the transmission by shifting through all gears (forward and reverse). It should engage smoothly without grinding or slipping.

- Articulated Steering: The steering system should be responsive and free of excessive play. Check for smooth operation during turns and ensure that the articulation joint is not loose or damaged.

-

Tire and Undercarriage Condition:

- Tires: Inspect the tire condition for wear, cuts, or cracks. Uneven wear can indicate an issue with alignment or suspension.

- Undercarriage: Check the undercarriage for any signs of damage, excessive wear, or rust. The condition of the chassis, frame, and rear axle can reveal the overall maintenance of the machine.

-

Cab and Comfort:

- Operator's Cabin: Inspect the cabin for wear and tear. The seat should be comfortable, and controls should be functional and easy to use.

- Air Conditioning: Ensure the air conditioning system works well, especially if you're operating in a hot climate.

- Visibility & Ergonomics: The cabin should provide good visibility, and all the essential controls should be within easy reach of the operator.

-

Service and Maintenance Records:

- Service History: Request the machine’s maintenance records. A well-maintained machine with a clear service history is likely to last longer.

- Previous Repairs: Verify if any major components have been replaced, such as the engine, transmission, or hydraulics.

-

General Physical Condition:

- Rust & Damage: Look for any visible signs of rust, cracks, or structural damage. This could indicate neglect or heavy use.

- Frame Integrity: Check for any signs of bending, warping, or cracks in the frame that may indicate prior accidents or poor usage.

Related Products