| Feature | Specification |

|---|---|

| Engine | Weichai WP10G175E301, 128 kW (172 HP) |

| Operating Weight | Around 21,000–22,000 kg |

| Transmission | 8 Forward + 4 Reverse speeds |

| Blade Width | 3.7 m (12 ft) |

| Maximum Blade Lift Height | 500 mm |

| Maximum Blade Depth | 610 mm |

| Turning Radius | 6.4 m |

| Fuel Tank Capacity | 320 L |

| Hydraulic Oil Tank Capacity | 180 L |

| Cab | Air-conditioned, ergonomic design, adjustable seat |

| Ground Clearance | 380 mm |

Second-hand XCMG GR2153 grader

Fob Price: / Unit

Product Description

TAG:

excavators-used.com

We have a huge collection of used construction machinery including excavators, loaders, bulldozers, cranes, and more. Contact us today!"

Key Areas to Inspect for a Second-hand XCMG GR2153 Grader

When buying a second-hand XCMG GR2153, it’s important to perform a thorough evaluation of its condition. Here are the main areas to focus on:

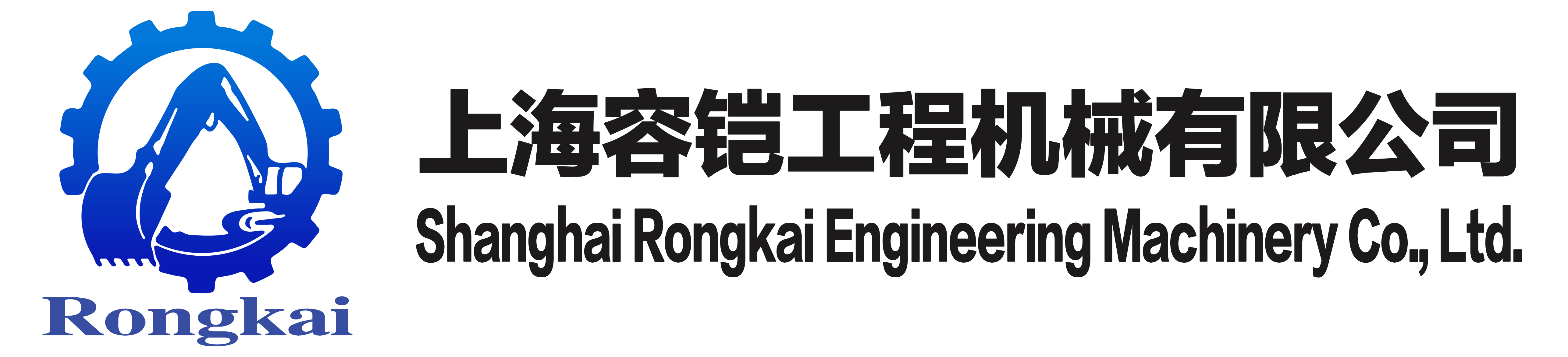

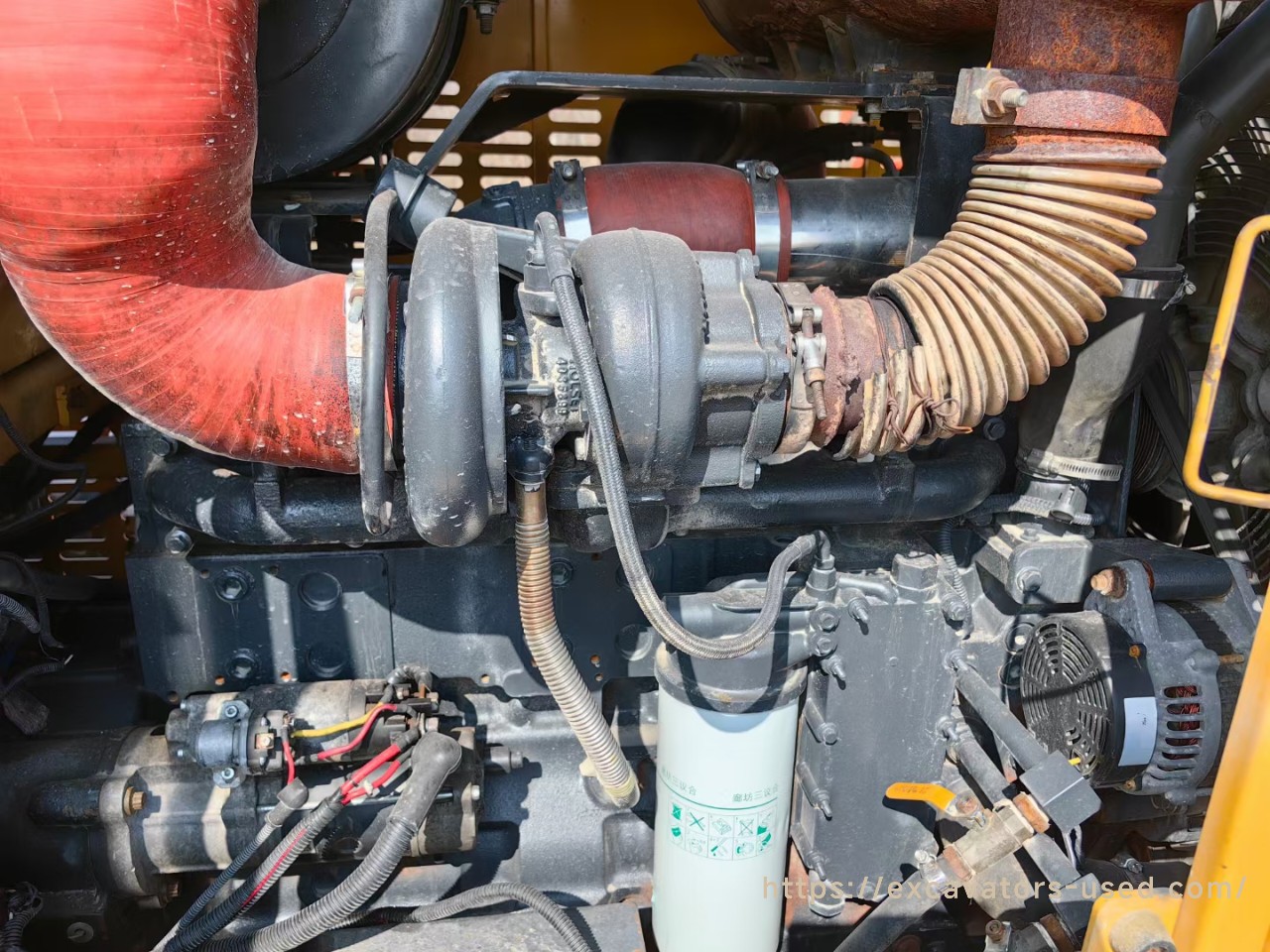

1. Engine and Powertrain

- Engine Condition: The GR2153 typically uses a Weichai WP10G175E301 engine, delivering 128 kW (172 HP). Ensure that the engine runs smoothly without abnormal noises, excessive exhaust smoke, or misfires.

- Oil Leaks: Check for oil leaks around the engine, transmission, and hydraulic components.

- Air Filters and Belts: Inspect air filters for cleanliness and check the belts for wear or damage.

2. Hydraulic System

- The hydraulic system controls the blade movement and other essential operations. Test the operation of the blade lift, tilt, and angle to ensure smooth, responsive control without jerks or delays.

- Inspect for hydraulic oil leaks around cylinders, valves, and hoses.

- Examine the hydraulic oil tank and check the oil’s condition; dirty or contaminated oil can indicate poor maintenance.

3. Transmission and Steering

- The GR2153 grader comes with an 8-speed transmission. Test all gears to ensure smooth transitions between forward and reverse gears. There should be no grinding or unusual sounds when shifting.

- Check the steering system for any play or unusual behavior, as it is critical for handling and maneuverability in the field. Ensure that the articulating frame and steering hydraulics are in good condition.

4. Undercarriage and Tires

- Inspect the undercarriage for signs of wear, especially around the frame, axles, and suspension. The GR2153 is a heavier machine, so ensuring the integrity of the undercarriage is vital for longevity.

- Tire Condition: Check the tires for tread wear, cuts, and cracks. Tires on a grader can be costly to replace, so make sure they have enough life left.

- Examine the front blade and scarifier to ensure they have not been excessively worn down.

5. Cab and Operator Controls

- Check the operator's cab for wear and tear. Ensure that the seat is comfortable and the air conditioning system works well.

- Verify that all controls (joystick, pedals, switches) are in working order. A malfunctioning control system can lead to safety concerns or operational inefficiencies.

- Ensure that the instrument panel displays accurate readings for oil pressure, fuel, and other critical systems.

6. Electrical System and Lights

- Inspect the wiring for any signs of damage or wear.

- Test the lights, indicators, and horn to ensure all electrical components are functional.

- Ensure that the batteries are in good condition and are properly secured.

7. Service and Maintenance History

- Request the maintenance and service records. A machine that has been serviced regularly according to the manufacturer’s recommendations will likely last longer and perform better.

- Look for records of any major repairs or part replacements, such as the engine, transmission, or hydraulic components.

8. Visual Inspection

- Check for signs of cracks or structural damage to the frame and chassis.

- Look for rust or corrosion, especially in areas exposed to harsh environmental conditions.

- Examine the blade edges and scarifier teeth for damage or wear. These components are subject to heavy use, and replacements can be costly.

Related Products